Application Of Abrasive Blasting & Shot Peening Process

- Remove heat treat scale, rust, corrosion and paint.

- Remove residual film from moulds and dies

- Remove slag, oxides and discoloration from weld joints

- Cleaning and debarring of ferrous and non ferrous castings

- To produce decorative matte of stain finish.

- To produce surface ideal for lubrication retention.

- To improve metal wear,finish and appearance.

- adequate working space around the job.

- adequate working space around the job.

- To prepare surface for Pre-place and Pre-anodize.

- To prepare surface for coating and painting.

- To exturizing and etching of rollers.

- De flashing and deburrning of thermo set plastic parts

- Shot peening for producing residual compressive stresses

- To improve strength, fatigue life and reduce corrosion

- Shot peening blades, gears, spring and Tranmission components.

Methods Of Abrasive Blasting

There are Basically three established methods of abrasive blasting i.e. INDUCTION - SUCTION ( SUPPER BLASTER), DIRECTOR PRESSURE (PRESSURE BLASTER) and SLURRY PUMPING ( WET BLASTER). These are briefly described below :

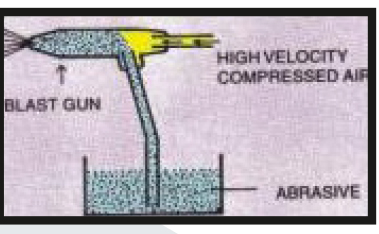

Induction -Suction

In this method abrasive is drawn from hopper into the blast gun by a partial vacuum created by high velocity airflow. This is useful for light-weight abrasive and cleaning of light corrosion.

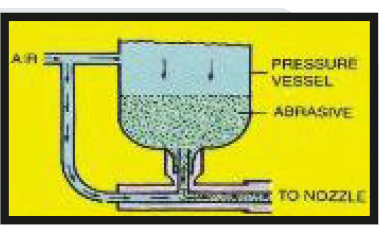

Direct Pressure

In this Method, abrasive is pressurized in a pressure vessel by compressed air and then for nozzle. it imparts high abrasive velocity and blasting is faster.

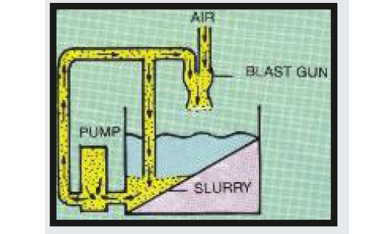

Slurry Pumping

in this method pump draws fine abrasive mixed in water (slurry) From Boon of hopper and forces it to blast gun where compress air is introduced to atomise the slurry. slurry impacted on the surface to be cleaned.

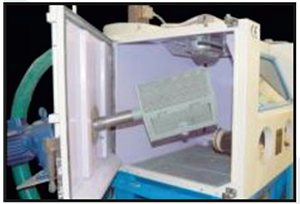

Finiprak-Suction Blaster

Work on INDUCTION-SUCTION principle of abrasive delivery. the super blaster ensures continuous Working and no interruption in blasting cycle. Recommended for light and medium size components where surface is to be cleaned or debarred or to impart with fine matte finish. Useful for heat treatment shops, tool, die and moulds makers and shot peening of light metal components etc. SB machines are incorporated With reclaimer which ensures uniform cleaning and finishing each me and in every next operation.this is achieved by an automatic system of abrasive cleaning and separation built into the reclaimer. Dust and debris are separated and only clean and sized abrasives are carried to blast gun-ensuring a homogeneous finishing. most cabinets of other make do not have the reclaimer as standard practice.

Options available on request

- • Rubber lining inside walls of cabinet.

- • Reverse jet cartridge filter dust collector

- • Higher output Blast Gun in place of standard

- • Foot operated treadle switch for blasting ON/OFF.

- • Field with optional accessories

Finiprak-Pressure Blaster

Works on direct pressure principle of blasting, the pressure blaster produces high abrasive velocity resulting to cleaning of job at faster rate. A pressure vessel directly bolted below hopper of cabinet has automatic abrasive refilling arrangement. A tubalar fabric bag type dust collector with/generous filter area is attached with cabinet as standard feature for high efficiency of dust collection. A manual shaker is also provided for bag shaking

PB is recommended for fast cleaning for removal of heavy rust and corrosion using coarse abrasive, it is most suitable for etching the surface needed for rubber-lining, FRP lining and metal spaying. casting and forgings are cleaned speedily. blast pressure can be controlled from 30 to 90 psig. almost all type of coarse and medium size abrasive can be used depending upon application.

Options available on request :

- • motorized bag shaking arrangement.

- • reverse jet cartridge filter dust collector.

- • higher output blast gun in place of standard.

- • foot operated treadle switch for blasting ON/OFF.

- • field with optional accessories.

Finiprak-Wet Blaster

Works on INDUCTION-SUCTION principle of blasting. The most important point in wet blasting is its ability to use very fine abrasive - as fine as 5 microns. fine abrasive parcels are suspended in liquid, usually water and then pumped. to a nozzle as a slurry. At nozzle, the slurry is introduced into air-stream and propelled against job.the gland less slurry pump is used to feed the slurry at positive pressure into blast gun.the wetted parts of pump are the thermo set plastic material for corrosion resistance.WB machine is useful in tool room to remove feather burrs from multi tooth Cutting tools, such as, milling cutters, holes,broaches and taps eliminating hors of hand honing me. It deburrning intersection holes in precision parts which are inaccessible by any other method.the finest machined surface can be super-finished without damage to sharp edges and exact tolerances.

Options available on request :

- • Higher capacity slurry pump for high output.

- • Higher output Blast Gun in place of standard

- • Foot operated treadle switch for blasting ON/OFF.

- • Field With optional accessories.

OPTIONAL ACCESSORIES

To increase your production, use following accessories with the blast cabinet

Tumble Basket

Tumble basket is mounted on side door to suit cabinet size. basket is easily removable when not needed. blast period is controlled by a mer. it is suitable for automatic batch blasting of smaller parts, such as balls, rings, screws, nuts, tools etc.

Tumble basket length / dia(mm) : 300/250 & 350/300

Load capacity (kg) : 20 & 25

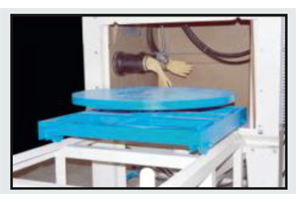

Inside Turntable

The turntable is fixed inside the cabinet on bearing for easy and free manual rotation of jobs.

Turn table diameter (mm) : 500 & 700

Load capacity (kg) : 50

Work car With Turntable &

Mounted Track Extension

The turntable is fixed on work car. the track extension is provided inside of cabinet to facilitate work car movement. it is deal for handling large and heavy components.

Work car Length (mm) : 600, 750 & 900

Track Extension Length (mm) : 1500