Airless Blasting Machine

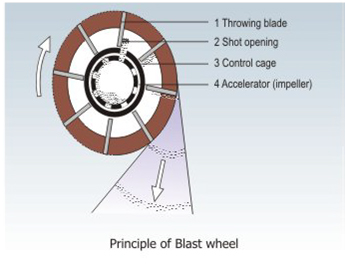

In Airless Blasting Machine the blast cleaning media is propelled by centrifugal blasting wheels. Automation is provided by Rotary Barrel, Tumblast, Swing Table, Hanger, Tunnel, Diabola etc.

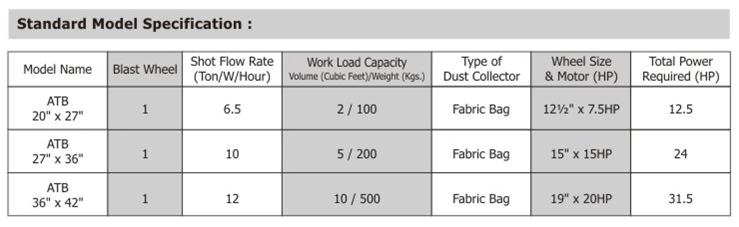

Tumblast

The machine is designed for automatic efficient shot blasting of castings and other metallic components having various sizes. The pieces are loaded into the Tumbling Barrel (Chamber) by Mechanical Loader where they are blasted. The shots, which have passed from the screen, are subjected to an air wash system, which drains all dust and broken shots. Only usable shots come to the storage hopper, and get re-cycled. The fines and broken shots come to a refuse hopper and are rejected from the system. The Dust Collector absorbs the fine dust produced in cabinet. A Mechanically operated Loader is provided to load the job in Tumbling Belt. Two Limit Switches have been provided for Loading operation.

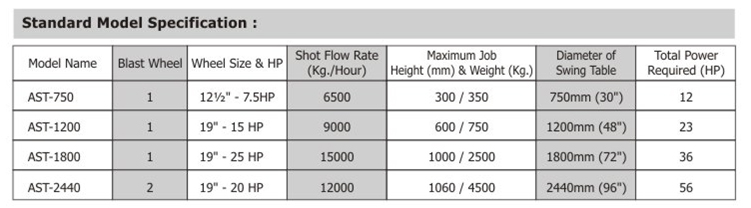

Swing Table Type

The machine is designed for automatic efficient shot blasting to De-scale and remove rust from job rotating on Rotating Turn Table. The Job is loaded on Door mounted Turn Table &fed in the Blasting Cabinet where they are blasted inside the chamber. The Job is loaded on the rotating table where they are blasted inside the work chamber (blast cabinet). After blasting, the shots fall down inside the hopper of the cabinet and are gravity fed to the lower screw conveyor. The screw conveyor conveys the shots from the cabinet tot the boot of the bucked elevator, which in turns lifts the shots and feed them to a rotating screen. The usable shots, unusable shots (fine) and heavy dust will be filtered through the screen and unusable shots (bigger size) and other big particles will stay on the screen and should be removed through refuse pipe time to time.

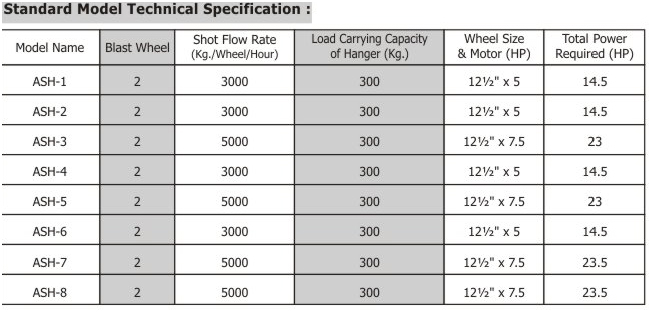

Hanger Type

The machine is designed for automatic efficient shot blasting of Aluminum Casting. The Job is loaded on the Hangers of Indexing Turn Table. The Job is loaded on the Hanger in the Blasting Cabinet where they are blasted inside the chamber. The speed of the Hanger drives can be regulated by AC drives. The cabinet is protected from erosion by LINERS (Hardened wear plates), mounted on the sidewalls, top & door The Dust particles generated in the system are collected in a number of Plated Bags in a dust collector. Clean air is exhausted through an exhaust fan. The Plated Bags are cleaned by Pulse type Reverse Jet air cleaner controlled through Solenoid Valve and the collected dust particles fall in a dust bin and taken out for disposal from time to time.

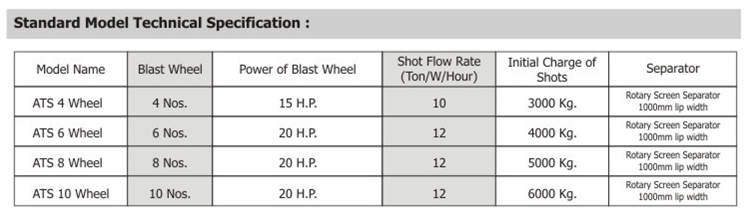

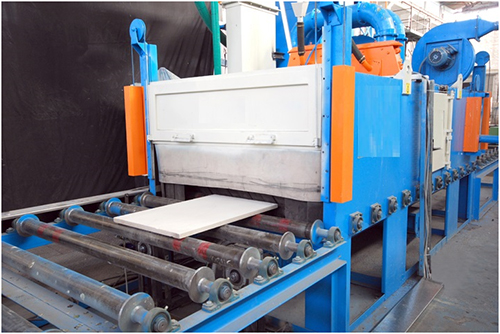

Tunnel Type

has a range of Airless Shot Blasting Machine 'Tunnel Type' with number of Blast wheels varying according to the production output required. This is the most used after & the most flourishing series for the long structural, channels, angles, plates, gratings, pipe etc. for large production output in terms of surface treatment. The opening of the tunnel & numbers of blast wheels, depend upon the structure of the job for attaining homogeneous finish. Major parts of the machine include blast wheel for giving high production output, roller conveyor for job conveying & the media recovery, consist of bucket elevator, screw conveyor, rotary screen separator etc. & pulse jet type dust collector. Airless Shot Blasting Machine Tunnel Type has unearthed major applications in cleaning the long structures like angles, channels, beams & flat structures like plate, gratings etc. for getting the finish SA2.5.

Diabola Type