Blast Room Floor Design

The Floor Design You Select Will Determine The Capabilities Of The Room, the Degree Of Lab our Involvement, Cost Of Purchase & Installation And return On Your Investment.

Screws : The floors utilize a heavy duty screw to return the abrasive to the separator/classification system.

-

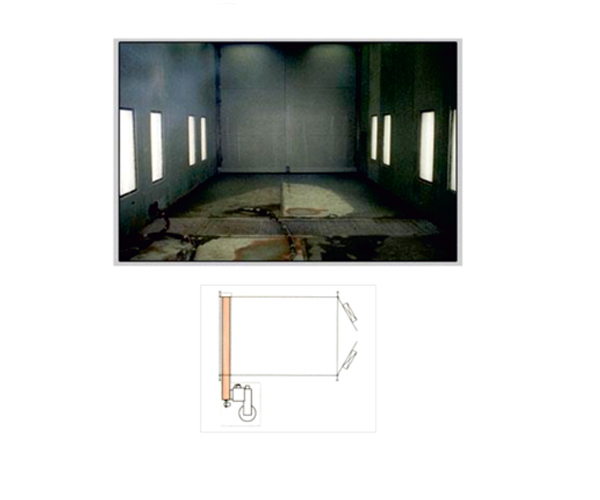

Single Screw Partial Recovery

This is the most economical floor design available. The system contains the major components found in all FINIMAC Blast Room Equipment Reclaim Systems, including metering shed plates, heavy-duty screw, belt & bucket elevator, air-wash separator, perforated plate rotary drum separator and over sized abrasive storage hopper with a caged man ladder & handrail. This is a basic "automatic reclaim package that can be expanded to an "H", "U" or Full Floor reclaim system. It is best suited for low to medium productive levels.

-

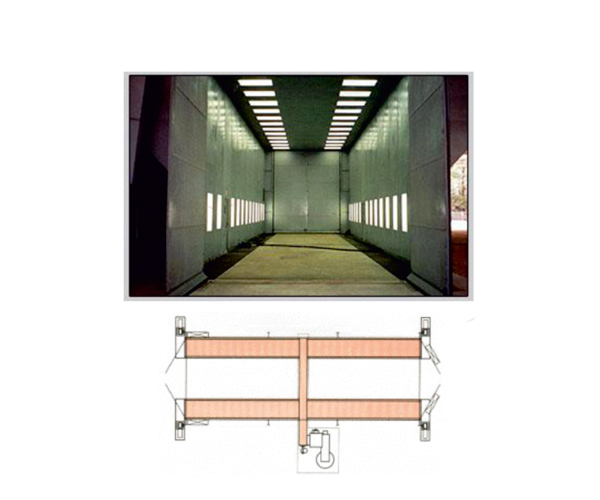

"H" Shaped Partial Recovery

The "H" shaped partial reclaim system adds two longitudinal metered screw assembly along each side wall of the blast room. The position of the screw assembly allows the abrasive delivered from the blasting nozzle, which is either blown or rebounded of the work piece, to strike the side walls and fall into the screws, automatically reclaiming approx. 60 — 90% of the blast media. "flow-through" The H shaped room floor configuration design is typically where heavy utilized work in a piece medium can to drive high production.

-

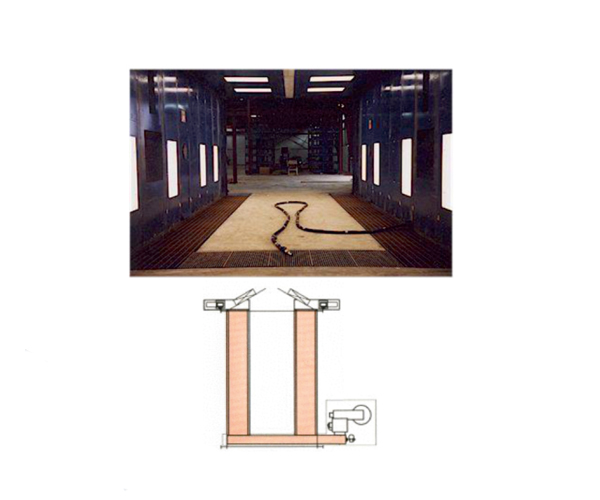

“U" Shaped Partial Recovery

The "U" shaped partial reclaim system adds two longitudinal metered screw assembly along each side wall of the blast room & positions the cross screw along the back wall of the blast room. A "U" shaped floor design will automatically reclaiming approx. 60 — 90% of the blast media & remaining abrasive on the floor is pushed into the metered shed plate screw assembly at the end of the work shift. The "H" shaped floor design is typically utilized in a "flow-through" room configuration where heavy work piece can drive into the room. This is best suited for medium to high production.

-

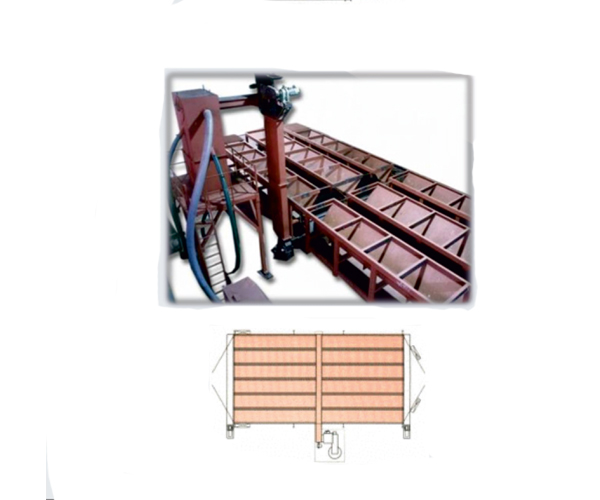

Full Floor Recovery

The full floor reclaim system utilizes multiple screw assembly to create a fully automatic abrasive reclaim system, where 100% of the blast media is returned to the separator system during the blasting operation. The full floor reclaim design requires that the material handling of the work piece be intricately designed into the configuration of the room. The full floor reclaim design can be used with any room configuration. This system is best suited for high production requirement.