Blast Room Abrasive Recovery & Separation System

All abrasive recovery system include three basic functions :

- Delivering the abrasive which rebounds off the work piece to a central recovery point.

- Transporting the abrasive from that central point to an abrasive cleaner.

- Removing dust, fines & other unwanted material from the abrasive before it enters the blast machine for re-use.

Mechanical Recovery System

Consists of Screw Conveyor System, Bucket Elevator & Abrasive Cleaner.

Bucket Elevator :

The buckets are of seamless type made of 3.15 mm thick steel sheet. Bucket Elevator is fabricated from MS material of 5 mm thick at

boot section 3.15 mm thick at trunk and top sections.

Blast Generator :

Blast tanks are positioned directly under the abrasive storage hopper & gravity feed. A covered riser assembly filters the abrasive through a perforated plate screen and contains the abrasive when the tanks exhaust, preventing abrasive leakage that may collect in the area.

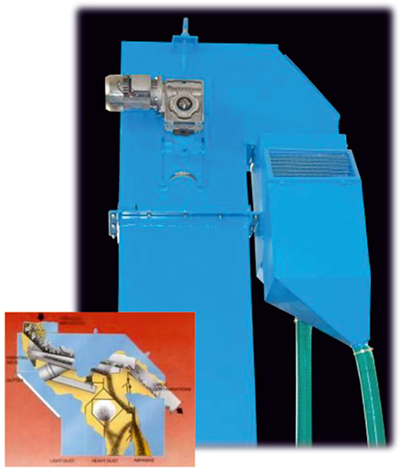

Abrasive Cleaner

The media separation unit is a air wash rotary screen separator which receives all media and debris from blasted work piece by the bucket elevator. Contaminants are removed by rotary screen and are are discharged through a chute. The finer contaminants are abrasive that passes through the screen then cascade over the air wash where fine contaminants and small abrasive particles are removed. Reusable abrasive falls in the machine.

Pneumatic Recovery System