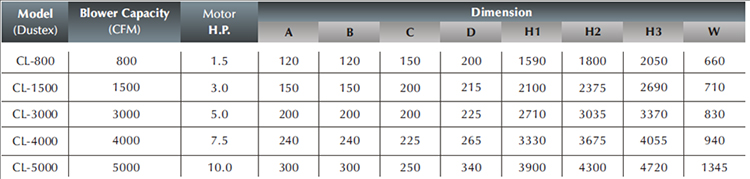

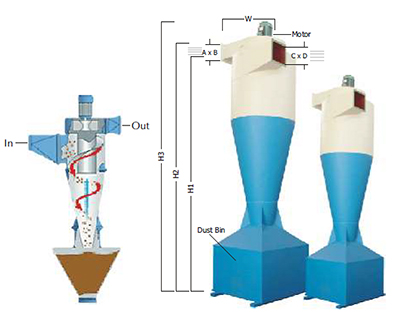

Cyclone Dust Collector

A cyclone dust collector is to separate any metallic or other dust particles from the spraying/ Blasting room and discharge clean air to the atmosphere. In this the suction created by Exhaust Fan causes the dust laden air to enter the Cyclone Dust Collector. In the cyclone the dust particles get separated by a centrifugal action and get settled in a Dust Tray at the bottom of the cyclone. The dust free clean air escaped to the atmosphere through the Exhaust Fan. There by allowing dust to be collected in the dust tray. The collected dust in a dust tray at the bottom of the Cyclone Dust Collector is taken out manually, from time to time.

Fabric Bag Dust Collector

How it Works: Dust laden air is drawn into dust collector through inlet due to suction created by exhaust fan and passes through fabric bags. Heavier dust particles fall into hopper due to loss of momentum. Finer dust gets deposited on inner surface of fabric bags and clean air passes across outer surface of filter bags and then exit into atmosphere through outlet. Bags are cleaned through motorized shaking arrangement. When motor is switched OFF, shaking cycle gets activated automatically and bags are shaken for preset time through timer. Dust released from filter bags slides downward into hopper for further collection into dust bin.

Special Features :

- Modular Design with no moving parts: :: Low maintenance and replacement of fabric bags is easy and quick.

- Fair Air to filter ratio : Assures longer Life of bags.

- Variety of fabric material : Fabric bags are normally of cotton woven satin cloth. However, other materials can be supplied to suit individual application.

Cartridge Dust Collector

How it Works: Dust laden air is drawn into dust collector through inlet due to suction created by exhaust fan and passes through filter cartridge elements. The abrasive resistant inlet promotes dropping out high particulate, generates uniform air flow, thus increases filter life. The dust gets deposited on outer surface of cartridges and clean air flows through the center passage of cartridge into clean air plenum. Clean air further exit into atmosphere through outlet duct. Cartridge are periodically and automatically get cleaned through air purging. Sequence circuit activates solenoid valves for high pressure air purging of preselected cartridges. Dust released from cartridges slides downward in to the hopper for further collection in to the dust bin.

Special Features :

- Down flow Principle : Assures high collection efficiency.

- Modular Design with no moving parts: Low maintenance and replacement of cartridge element is easy and quick.

- Fair Air to filter ratio : Assures longer Life of cartridges

- Variety of fabric material : Cartridges are normally of synthetic webbed material. However, other materials can be supplied to suit individual application.

- Quality & reliability : Dependable products with in-build quality for trouble free operation.

Pleated Bag Dust Collector

How it Works: Dust laden air is drawn into dust collector through inlet due to suction created by exhaust fan and passes through Pleated Bag elements. The abrasive resistant inlet promotes dropping out high particulate, generates uniform air flow, thus increases filter life. The dust gets deposited on outer surface of Pleated Bag and clean airflows through the center passage of Pleated Bag into clean air plenum. Clean air further exit into atmosphere through outlet duct. Pleated Bag are periodically and automatically get cleaned through air purging. Sequence circuit activates solenoid valves for high pressure air purging of preselected Pleated Bag. Dust released from Pleated Bags slides downward into the hopper for further collection into the dust bin.

Special Features :

- Fair Air to Filter ratio : Assures Longer Life to Cartridges

- Variety of Material : Cartridges are normally of synthetic Webbed material. However, other material can be supplied to suit individual application.

- Modular design with no moving Parts

Typical Application for Ventilation & Dust Collector :

- Shot Blasting Room

- Metal and Powder Spraying Enclosures

- Plasma Spray Acoustic Chamber

- Smoke and Welding Fume Extraction

- Wherever Dust Extraction is a Necessity.

Dust Collector Accessories / Spares